How to easily judge the use status of hydraulic oil of injection molding machine

The hydraulic transmission of the injection molding machine uses hydraulic oil as the working medium, and uses the pressure energy of the hydraulic oil in the sealed working volume to transmit energy or power or signal. The quality of hydraulic oil and seals directly affects the stable operation of the hydraulic system and indirectly affects the quality of products. To prevent and reduce the failure of hydraulic system, reduce wear and prolong life, we should strictly use and maintain hydraulic oil.

Generally speaking, 70% of hydraulic failures are caused by incorrect or improper use and maintenance of hydraulic oil. Maintaining good maintenance habits and preventive maintenance is the most effective way to reduce and prevent hydraulic failures in your machine. Therefore, the refined maintenance of hydraulic oil and hydraulic system is very important. Therefore, it is necessary to introduce the characteristics and requirements of hydraulic oil.

The most important properties of hydraulic oil are viscosity and cleanliness, as well as good anti-oxidation, anti-wear, anti-foam, anti-corrosion properties and good lubricating properties.

The viscosity of hydraulic oil is expressed by the average value of the kinematic viscosity at a temperature of 40°C. Our commonly used No. 46 anti-wear hydraulic oil (46csT/40℃) means that the average kinematic viscosity of this hydraulic oil is 46m2/S when the temperature is 40℃.

The relationship between hydraulic oil viscosity and pressure and temperature is as follows: when the temperature increases, the viscosity decreases; when the pressure increases, the viscosity increases.

Periodic testing of hydraulic oil performance. If the oil is contaminated or deteriorated, the life of the injection molding machine will be shortened and failure may occur. It is therefore necessary to test the oil regularly to detect changes in oil properties. Based on this, decide whether to change the oil.

We can use a simple visual method (the best data value can be detected by a professional laboratory if possible) to understand the condition of the oil:

Appearance test. Put the new oil sample and the used oil sample in their respective test tubes and compare their color, clarity, floats present and water settling at the bottom of the test tubes, etc.

Drop test. Drop the old oil on the filter paper (blot dry) and observe it after 1h. If the oil is dirty or visibly spoiled, contamination will be easily observed.

Finger rubs. Rub the old oil in use on your fingers. If the viscosity decreases and deteriorates, the hand feels very rough and there is no thick feeling. The oil droplets fall off the fingers smoothly, and there is no thick rebound phenomenon.

Main Features:

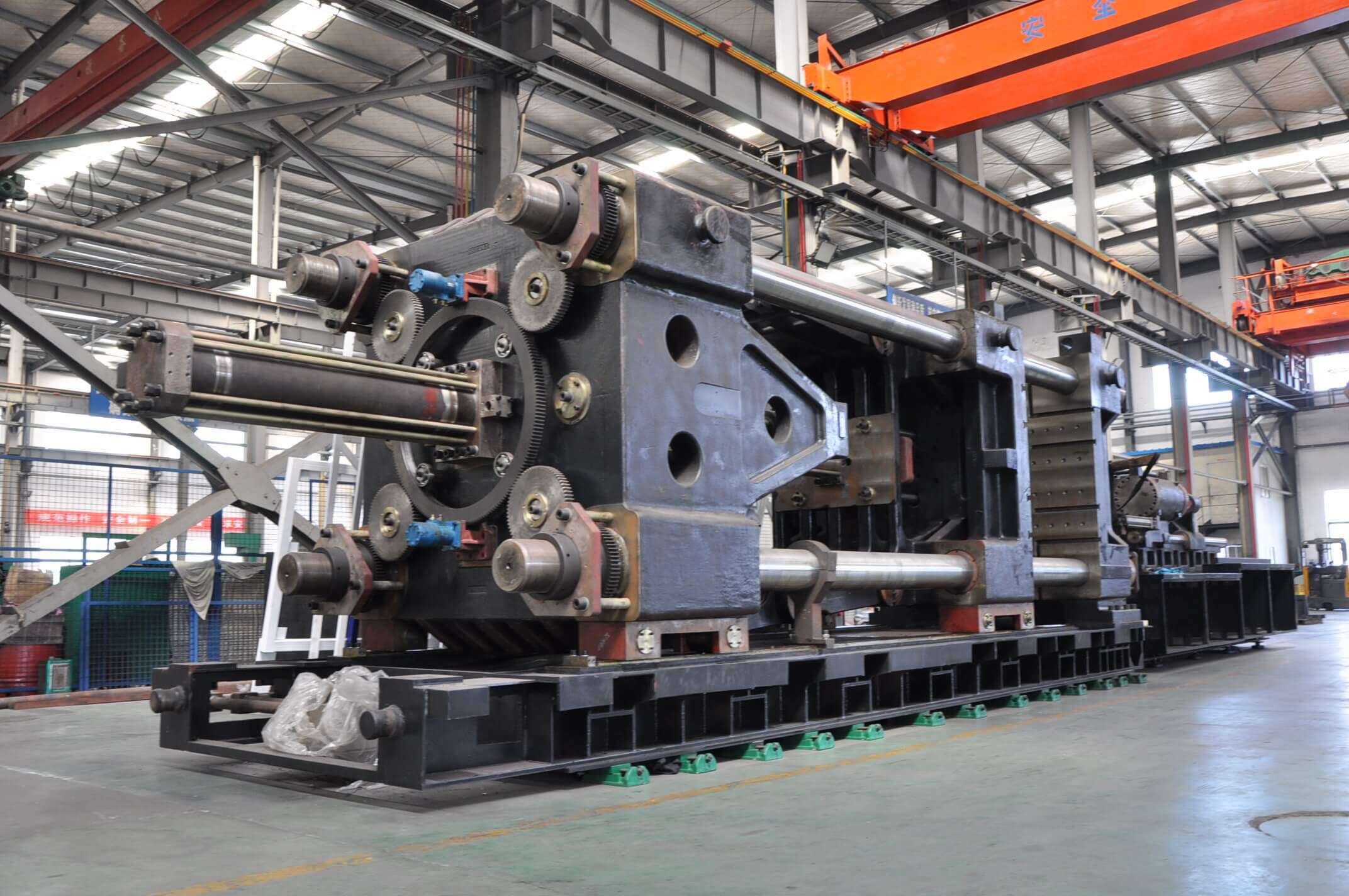

One.The Lock Section

1.Arch template, effectively protects the mould, especially suitable for big template with small mold.

2.The electric ruler is installed on the crosshead, the position is more precise.

3.The front connecting rod uses connected structure, increases the rod strength, and easy for assembly

4.The connected tail-board stills itself with big lock shaft, improves tail-board strength, and ensures zero abrasion of the tail-board, easy for maintenance.

5.Connected movable plate, improves its rigidity and reduces deformation

6.Connected thrust bearing, improves its strength and stills itself with small lock shaft, ensures zero abrasion.

7.Arch template fully complies with mechanical property, largely improves template strength.

8.More reasonable toggle design, speeds and stabilizes mold opening and closing.

9.Adjustable movable plate mounting plate, makes the installation easier.

10.Mixed design of T-shape groove and die hole, increases universality of the mold.

Two.The Injection Section.

1.Bridge type support, improves injection smoothness.

2.Longer length-diameter ratio screw design, improves plasticizing effect.

3.Double seal structure, ensures no oil leakage.

4.Withhold type press plate, easy for debugging and assembly.

5.Bijection structure, improves stability.